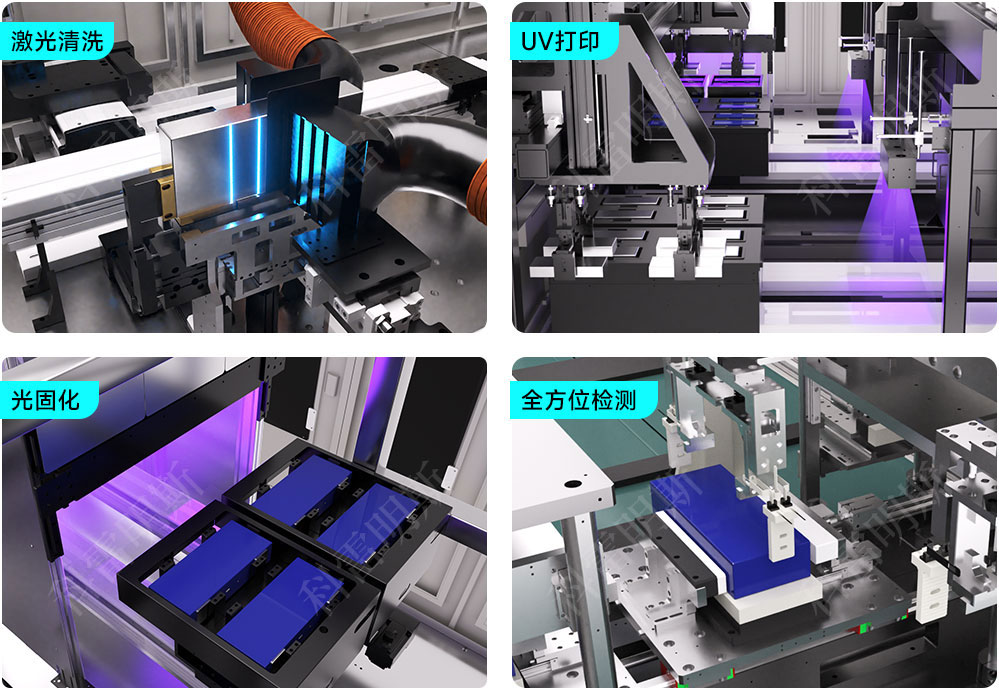

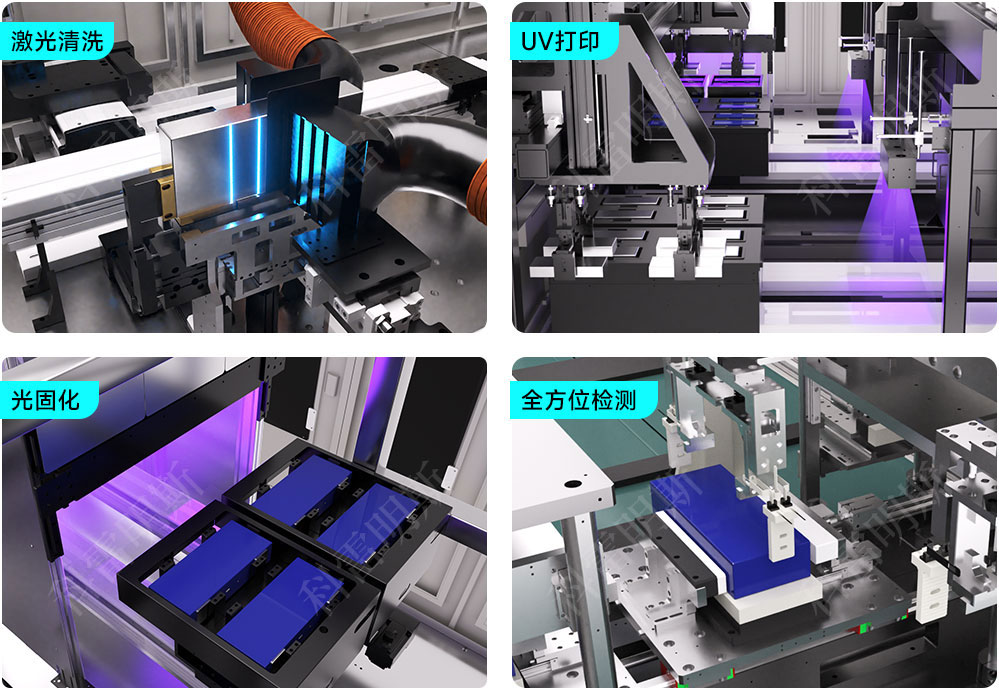

Integrated solution for UV insulation printing of CLIMAX battery cells: dual innovation of efficiency and quality

2025/8/1 10:55:24

Integrative solution for UV insulation printing of electric core of Climax: dual innovation of efficiency and quality

Scheme advantages:

Flexible Production

Compatible with electric cores of different size ranges, and can be printed on 5 or 6 sides, and the printing film thickness can be arbitrarily selected; Windows can be opened at will, and windows can be opened in areas without insulation protection such as pole, explosion-proof valve and QR code.

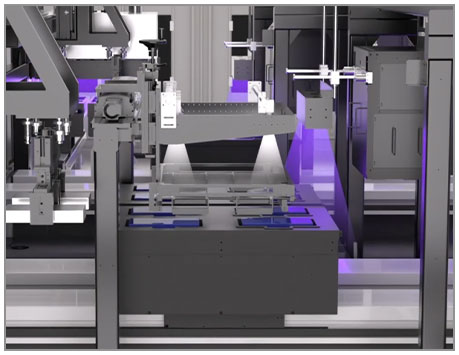

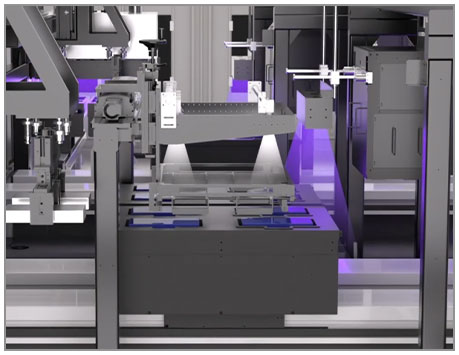

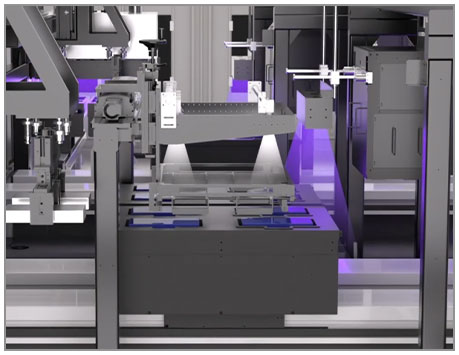

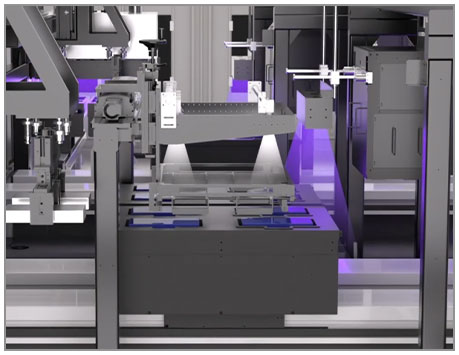

High production efficiency

High production efficiency

Multi-process seamless connection, second UV curing process, greatly shortened the curing time, modular design of production line equipment, increased printing module single-line capacity up to 60PPM.

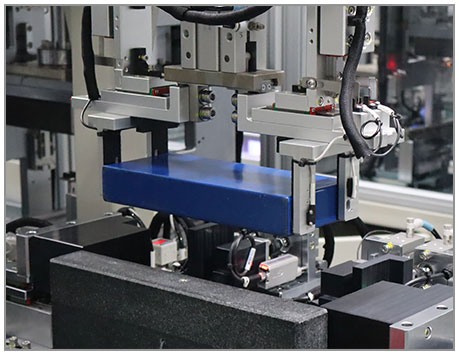

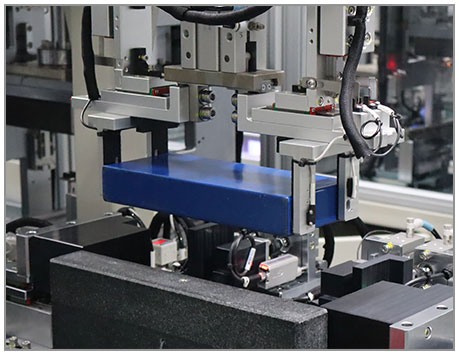

High precision

High precision

CCD visual positioning system is adopted to collect the dimension parameters of the incoming electric core, automatically generate the matched printing pattern according to the incoming electric core, and realize high-precision printing through the algorithm, with the positioning accuracy of ± 0.1mm, effectively guaranteeing the accurate fit between the insulation layer and the electric core outline.

High yield and good consistency

High yield and good consistency

Micron UV insulation printing process and comprehensive insulation and withstand voltage test are adopted to achieve the first-pass yield ≥ 98% and the final yield ≥ 99.9%; Improve the effective output per unit time of the production line and enhance the competitive advantage of the enterprise.

High material utilization rate

High material utilization rate

The material utilization rate is ≥ 99.5%, which can effectively optimize the material cost structure and reduce the resource consumption. It not only achieves the economic improvement, but also conforms to the green manufacturing and sustainable development concept, helping to build the resource university circulation production mode.

Integrated appearance

Integrated appearance

Six-side one-piece molding film, no crease, no bubble and no obvious particle on the film edge; The top insulation and overall film forming are completed synchronously, eliminating the independent lamination process, effectively improving the insulation layer consistency and production continuity, and reducing process redundancy.